Hot Air Oven’s

Hot air ovens are electrical devices which use dry heat to sterilize. They were originally developed by Pasteur.[1] Generally, they use a thermostat to control the temperature. Their double walled insulation keeps the heat in and conserves energy, the inner layer being a poor conductor and outer layer being metallic. There is also an air filled space in between to aid insulation. An air circulating fan helps in uniform distribution of the heat. These are fitted with the adjustable wire mesh plated trays or aluminium trays and may have an on/off rocker switch, as well as indicators and controls for temperature and holding time. The capacities of these ovens vary. Power supply needs vary from country to country, depending on the voltage and frequency (hertz) used. Temperature sensitive tapes or biological indicators usinbacterial sporesg can be used as controls, to test for tefficacyhe of the device during use.

Vacuum Oven’s

Vacuum ovens are very versatile pieces of equipment with applications in laboratory research, engineering, and industry. A vacuum drying oven is most often used for delicate drying processes, such as drying tiny parts or removing flammable solvents. The low pressure environment also minimizes oxidation during drying.

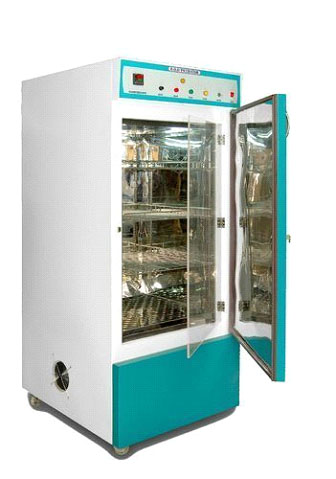

Incubator’s

An incubator is a device used to grow and maintain

microbiological cultures or cell cultures. The incubator maintains optimal temperature, humidity and other conditions such as the CO2 and oxygen content of the atmosphere inside. Incubators are essential for much experimental work in cell biology, microbiology and molecular biology and are used to culture both bacterial and eukaryotic cells.

The simplest incubators are insulated boxes with an adjustable heater, typically going up to 60 to 65 °C (140 to 150 °F), though some can go slightly higher (generally to no more than 100 °C). The most commonly used temperature both for bacteria such as the frequently used E. coli as well as for mammalian cells is approximately 37 °C (99 °F), as these organisms grow well under such conditions. For other organisms used in biological experiments, such as the budding yeast Saccharomyces cerevisiae, a growth temperature of 30 °C (86 °F) is optimal.

More elaborate incubators can also include the ability to lower the temperature (via refrigeration), or the ability to control humidity or CO2 levels. This is important in the cultivation of mammalian cells, where the relative humidity is typically >80% to prevent evaporation and a slightly acidic pH is achieved by maintaining a CO2 level of 5%.

BOD Incubator’s

BOD incubators are especially useful for determining levels of organic matter and nitrogen in waste water samples. These incubators are also called low temperature incubators. The BOD incubator provides the required temperature for the growth of microorganisms and allows to perform the BOD testing.

Sensor’s

A sensor is a device that produces an output signal for the purpose of sensing a physical phenomenon.

In the broadest definition, a sensor is a device, module, machine, or subsystem that detects events or changes in its environment and sends the information to other electronics, frequently a computer processor. Sensors are always used with other electronics.

Sensors are used in everyday objects such as touch-sensitive elevator buttons (tactile sensor) and lamps which dim or brighten by touching the base, and in innumerable applications of which most people are never aware. With advances in micromachinery and easy-to-use microcontroller platforms, the uses of sensors have expanded beyond the traditional fields of temperature, pressure and flow measurement.

Analog sensors such as potentiometers and force-sensing resistors are still widely used. Their applications include manufacturing and machinery, airplanes and aerospace, cars, medicine, robotics and many other aspects of our day-to-day life. There is a wide range of other sensors that measure chemical and physical properties of materials, including optical sensors for refractive index measurement, vibrational sensors for fluid viscosity measurement, and electro-chemical sensors for monitoring pH of fluids.

A sensor’s sensitivity indicates how much its output changes when the input quantity it measures changes. For instance, if the mercury in a thermometer moves 1 cm when the temperature changes by 1 °C, its sensitivity is 1 cm/°C (it is basically the slope dy/dx assuming a linear characteristic). Some sensors can also affect what they measure; for instance, a room temperature thermometer inserted into a hot cup of liquid cools the liquid while the liquid heats the thermometer. Sensors are usually designed to have a small effect on what is measured; making the sensor smaller often improves this and may introduce other advantages.

Technological progress allows more and more sensors to be manufactured on a microscopic scale as micro sensors using MEMS technology.In most cases, a micro sensor reaches a significantly faster measurement time and higher sensitivity compared with macroscopic approaches.Due to the increasing demand for rapid, affordable and reliable information in today’s world, disposable sensors—low-cost and easy‐to‐use devices for short‐term monitoring or single‐shot measurements—have recently gained growing importance. Using this class of sensors, critical analytical information can be obtained by anyone, anywhere and at any time, without the need for recalibration and worrying about contamination

PPI with Sensor’s

Proton pump inhibitors are used to: Relieve symptoms of acid reflux, or gastroesophageal reflux disease (GERD). This is a condition in which food or liquid moves up from the stomach to the esophagus (the tube from the mouth to the stomach). Treat a duodenal or stomach (gastric) ulcer.

Proton pump inhibitors are used to: Relieve symptoms of acid reflux, or gastroesophageal reflux disease (GERD). This is a condition in which food or liquid moves up from the stomach to the esophagus (the tube from the mouth to the stomach). Treat a duodenal or stomach (gastric) ulcer.